Technical

Inspections

for Oil & Gas

Specialists in non-destructive testing, industrial radiography and quality control.

Inspection

Services

More and more industries are using Non-Destructive Testing, as it allows for evaluation without losing production or putting structures at risk during studies.

We offer the best and most advanced Non-Destructive Testing quality services with highly qualified personnel, extensive track record and experience. Through the implementation of specific methods and appropriate technology, we provide important information about the condition of your structures.

Our work helps prevent accidents and produce economic benefits. Ensuring the quality and reliability of structures, and contributing to the development of materials science.

Affiliated with major Chambers of Commerce

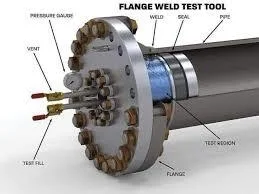

High-Pressure Elements Inspection

Specialization in critical components for Oil & Gas operations with cutting-edge technology and international regulatory compliance.

We have portable and stationary high-pressure testing pumps (up to 20kpsi). We also have our own bunker at the Neuquén base, and qualified personnel to perform periodic inspection of high-pressure elements.

We perform LEVEL 1 and LEVEL 2 INSPECTIONS AND HYDROSTATIC TESTING of elements and components for Coiled Tubing, Fracturing, Wire Line, MPD, Flow Back, Testing, Pressure Vessels, Choke Line and Well Control Systems.

Technical Capabilities

Applications

Applicable Standards

Inspection Methods

Non-Destructive Testing

Specialized techniques for evaluating the integrity and quality of equipment and facilities in the Oil & Gas industry, following international standards.

Types of Technical Inspection

Specialized Services

Explore our different types of technical inspection with detailed images of processes and specialized equipment in the Oil & Gas industry.

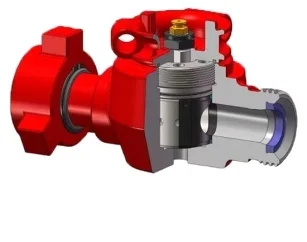

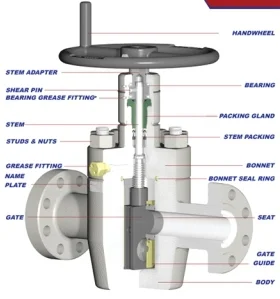

We offer LEVEL 1 AND LEVEL 2 inspection and maintenance of valves: BALANCED PLUG, BALL VALVES, GATE VALVES, CHECK VALVES, HYDRAULICALLY ACTUATED, PNEUMATICALLY ACTUATED.

Included Services:

- Inspection, lubrication, assembly and disassembly

- Kit replacement and maintenance

- Actuator replacement

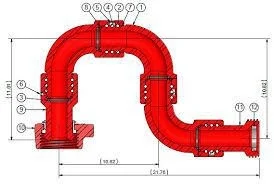

We offer inspection and maintenance of various chicksans with level 1 and level 2 inspection protocols according to international standards.

Included Services:

- Level 1 visual inspection

- Level 2 detailed inspection

- Integrity certification

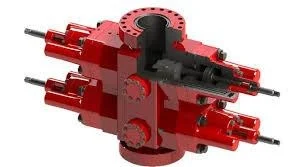

BOP Inspection: Hydrostatic testing of seals, RAM elastomer replacement, ANNULAR, PARTIAL AND FULL hydrostatic testing.

Included Services:

- Hydrostatic testing of seals

- RAM elastomer replacement

- Integrity testing

Specialized inspection of equipment in accordance with API 6A standard, including verification of technical specifications and certification.

Included Services:

- API 6A specification verification

- Conformity certification

- Detailed technical reports

Technical inspection in accordance with ASME B31.3 standard for process systems, including design verification and safe operation.

Included Services:

- ASME B31.3 verification

- Integrity assessment

- Compliance certification

Specialized inspection of manifold systems, plug catchers and sand separators to ensure optimal performance and operational safety.

Included Services:

- Manifold inspection

- Plug catcher verification

- Sand separator maintenance

Complete inspection of hoses and flexible hoses used in Oil & Gas operations, including integrity and pressure verification.

Included Services:

- Visual and dimensional inspection

- Hydrostatic pressure testing

- Connection verification

Contact us for your Project

Our team of specialists is ready to advise you and develop the perfect solution for your project in the Oil & Gas industry.

Central Administration

Rep. Argentina Este y Juan J. Castelli

Neuquén Administration

Av. Argentina 197 - 5° Piso Oficina B

Operational Bases

Strategic locations in Neuquén basin

Specialized Bases

Base Kompass

Puesto Cofre 260 • (+54 9) 299 465 3297

Base Kompass II

Pasaje Pullehue y Auquinco • (+54 9) 299 324 1153

Base Team Pumps

Pasaje Pullehue y Auquinco • (+54 9) 299 590 4031

Base WTS del Sur

Pasaje Pullehue y Auquinco • (+54 9) 299 409 6126

Metalúrgica LyA

Ruta 5 y Av. Argentina • (+54 9) 299 412 1555

Hotel El Portal

Primeros Pobladores Este y Ruta 6 • (+54) 299 573 8468

Complejo Habitacional Añelo

Avenida 91 y Calle 19 • (+54 9) 299 574 7481

Request Quote

* Required fields.